How to ensure that material enters the planetary screw extruder at a steady rate?

In the plastics processing and food processing industries, Planetary screw extruders are favored for their unique design and efficient mixing and plasticizing capabilities. In order to ensure that the material enters the extrusion system at a stable rate, the feeding system needs to be carefully designed and optimized.

What is Planetary Screw Extruder?

1. Definition and Use

Definition:

Planetary Screw Extruder is an advanced equipment for plastic processing. The unique planetary screw structure can achieve more complete material mixing and plasticization. This equipment is widely used in the production of thermoplastic products such as sheets, plates and films. The design principle is to form a planetary motion through the rotation of multiple screws around the central screw to achieve efficient mixing and plasticization of materials.

Uses:

Sheets and plates: used to produce various plastic plates and sheets, such as PVC sheets, PE sheets, etc.

Films: used to produce various plastic films, such as packaging films, agricultural films, etc.

Pipes and profiles: used to produce various plastic pipes and profiles, such as PVC pipes, PE pipes, etc.

2 Design Principles

The design principle of Planetary Screw Extruder is to form a planetary motion through the rotation of multiple screws around the central screw to achieve efficient mixing and plasticization of materials. It can produce stronger shearing and kneading effects, so that the materials can be more fully mixed and plasticized during the processing.

Planetary screw structure:

The planetary screw structure consists of a central screw and multiple planetary screws rotating around the central screw. The relative movement between the central screw and the planetary screw can produce stronger shearing and kneading effects, improving the mixing and plasticizing efficiency of the materials.

Efficient mixing and plasticizing:

The planetary screw structure of the Planetary Screw Extruder can make the materials more fully mixed and plasticized during the processing. It can improve processing efficiency, product quality, and reduce material waste.

3 Application areas

Processing of heat-sensitive materials: such as PVC.

Mixing of general plastics and engineering plastics: suitable for the processing of a variety of plastic materials.

Processing of heat-sensitive materials:

Planetary Screw Extruder is suitable for the processing of heat-sensitive materials, such as PVC. The unique planetary screw structure can make the materials more fully mixed and plasticized during the processing, improving processing efficiency and product quality.

Mixing of general plastics and engineering plastics:

Planetary Screw Extruder is suitable for processing a variety of plastic materials, including general plastics and engineering plastics. The efficient mixing and plasticizing capabilities can meet the processing requirements of different plastic materials and improve production efficiency and product quality.

Working principle of planetary screw extruder

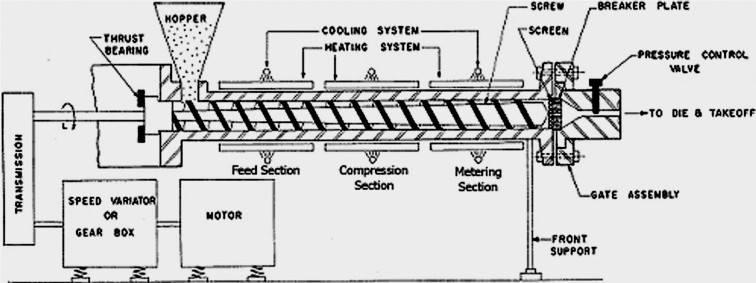

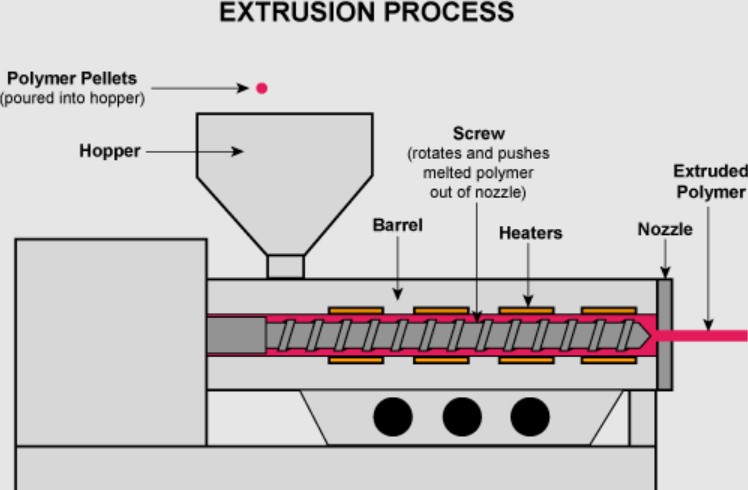

The working principle of Planetary screw extruders is based on its unique planetary screw structure. The material enters the barrel of the extruder through the feeding system, and the central screw and the planetary screw rotating around it work together to shear, extrude and mix the material. The central screw is responsible for conveying and plasticizing the material, while the planetary screw generates strong shear force with the central screw and the inner wall of the barrel through rotational motion, which refines the material particles and improves the mixing uniformity and plasticizing effect. This structure allows the material to be fully mixed and plasticized in the barrel, and finally extruded from the end of the barrel to form the desired shape and size.

What are the main features of Planetary Screw Extruder?

1 Unique planetary screw design

Planetary Screw Extruder adopts a unique planetary screw structure, which allows the material to be more fully mixed and plasticized during the processing process, improving processing efficiency and product quality. The design of the planetary screw can produce stronger shearing and kneading effects, improving mixing and plasticizing efficiency.

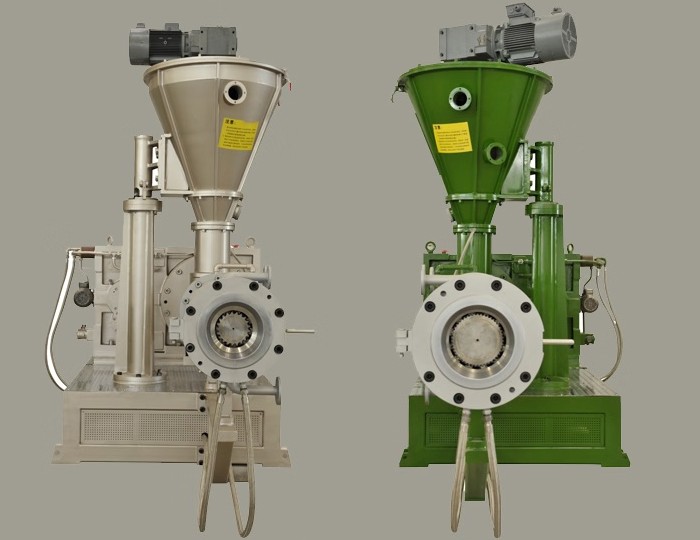

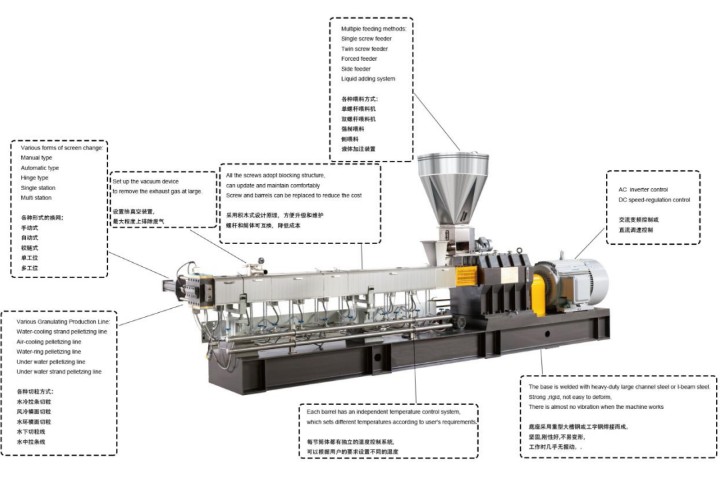

2 Forced feeding device

The equipment is equipped with a forced feeding device to ensure that the material enters the extrusion system at a sufficient rate and prevents bridging in the hopper, ensuring the continuity and stability of the production process. The forced feeding device can ensure that the material enters the extruder evenly and continuously to avoid material accumulation and blockage.

3 Accurate and stable temperature control

Planetary Screw Extruder includes a water-cooled circulation system for the screw and barrel in the feeding section, and an oil-heated circulation system in the planetary section, ensuring accurate and stable temperature control throughout the extrusion process. Accurate temperature control can ensure uniform plasticization and mixing of materials during processing and improve product quality.

| Features | Description |

| Unique planetary screw design | Make the material more fully mixed and plasticized during the processing, improve processing efficiency and product quality. |

| Forced feeding device | Ensure that the material enters the extrusion system at a sufficient rate and prevent bridging in the hopper. |

| Accurate and stable temperature control | Ensure uniform plasticization and mixing of materials during processing to improve product quality. |

What are the common faults and solutions of Planetary Screw Extruder?

1 Unstable temperature control

Fault manifestation: The temperature of the extruder fluctuates greatly, affecting product quality.

Solution: Check the water-cooled circulation system and the oil-heated circulation system to ensure their normal operation. Regularly clean impurities and blockages in the circulation system to ensure the smooth flow of the circulation system.

2 Poor material feeding

Fault manifestation: Uneven material feeding affects production efficiency.

Solution: Check the forced feeding device to ensure that it works properly and prevent bridging in the hopper. Clean the residual materials in the hopper and feeding device regularly to ensure smooth feeding of materials.

3 Equipment wear

Fault manifestation: The screw and barrel are seriously worn, affecting the service life of the equipment.

Solution: Check the wear of the screw and barrel regularly and repair or replace them in time. In daily use, pay attention to the lubrication and maintenance of the equipment to extend the service life of the equipment.

| Fault type | Fault manifestation | Solution |

| Unstable temperature control | Large temperature fluctuation of extruder | Check water cooling circulation system and oil heating circulation system |

| Poor material feeding | Uneven material feeding | Check forced feeding device |

| Equipment wear | Screw and barrel are seriously worn | Check regularly and repair or replace in time |

Temperature control system of planetary screw extruder

The temperature control system of Planetary screw extruders is responsible for adjusting the temperature of the screw and barrel to ensure the melting and plasticizing effect of the material. The temperature control system usually includes a heating device and a cooling device, which ensures that the material is processed within a suitable temperature range by accurately controlling the temperature. The heating device can be an electric heater or a steam heater, which is used to provide sufficient heat at the beginning of the material entering the barrel to make it reach a molten state. The cooling device is used to moderately cool the material after plasticization to prevent overheating and material degradation or adhesion. The temperature control system monitors the temperature of the screw and barrel in real time through sensors, and automatically adjusts the power of the heating and cooling devices according to the set temperature parameters to achieve precise temperature control.

Installation and commissioning of planetary screw extruder

The installation and commissioning of Planetary screw extruders need to follow certain steps and requirements.

First select a suitable installation site to ensure that the ground is flat and solid, and leave enough space for operation and maintenance.

Place the equipment stably on the foundation and perform horizontal correction to ensure the stability and safety of equipment operation.

Connect the power supply and cooling water system to ensure that the power supply voltage and frequency meet the equipment requirements and the cooling water system is unobstructed.

After the installation is completed, the equipment is debugged, including checking whether the connection of each component is firm, starting the motor and observing the operation of the screw and planetary screw to ensure no abnormal noise and vibration.

Set appropriate temperature parameters through the temperature control system, and conduct a trial run to observe the melting and plasticization effects of the material, and adjust according to the actual situation until the ideal processing effect is achieved.

Design principle of feeding system

1. Main function

The feeding system is one of the key components of the Planetary screw extruders.

The main function is to feed the material into the extrusion system at a stable and uniform rate.

2. Use forced feeding device

In order to achieve stable feeding, the feeding system usually uses a forced feeding device.

The forced feeding device pushes the material into the feed port of the extruder through mechanical force to ensure the continuity and stability of the material.

3. Design basis

The design of the forced feeding device is based on the physical properties and processing requirements of the material.

By accurately controlling the speed and pressure of the feeding device, the feeding rate of the material can be adjusted to ensure that it matches the processing capacity of the extrusion system.

4. Sealing performance

The feeding device should have good sealing performance to prevent the entry of external impurities.

Ensure the purity of the material and avoid the influence of impurities on the processing and product quality.

Pretreatment of materials

1. Importance of pretreatment

Before the material enters the planetary screw extruder, proper pretreatment of it is an important step to ensure stable feeding. Pretreatment can improve the fluidity and uniformity of the material and make it easier to be transported by the feeding system.

2. Pretreatment process

Pretreatment mainly includes processes such as drying, crushing and mixing of materials.

3. Drying of materials

Importance: Materials with too high humidity are prone to bubbles and uneven melting during extrusion, affecting the quality of the final product.

Method: Through drying treatment, moisture in the material can be removed.

Effect: Ensure the stability and consistency of the material during the extrusion process.

4. Crushing of materials

Purpose: Through crushing treatment, large pieces of material can be broken into small particles.

Effect: Improve the fluidity and uniformity of the material.

5. Mixing of materials

Purpose: Mixing treatment can ensure that the composition of the material is evenly distributed.

Importance: Avoid processing problems caused by uneven composition.

Control technology of feeding device

In order to achieve stable feeding of materials, the feeding device needs to be precisely controlled. Modern planetary screw extruders usually use advanced control systems to monitor and adjust the feeding device in real time through sensors and controllers.

The control system monitors the flow, pressure, temperature and other parameters of the material in real time through sensors installed on the feeding device. According to the changes in these parameters, the controller can automatically adjust the speed and pressure of the feeding device to ensure that the material enters the extrusion system at a stable rate. The control system can also be linked with other parts of the extrusion system to achieve automation and intelligence of the entire processing process.

Material conveying pipeline design

The material conveying pipeline is a bridge connecting the feeding device and the extrusion system, and its design has an important influence on the stable feeding of the material. The conveying pipeline should have good fluidity and sealing to ensure the stability and purity of the material during the conveying process.

The design of the conveying pipeline should take into account the physical properties and processing requirements of the material. By reasonably selecting the material, diameter and length of the pipeline, the resistance and loss of the material during the conveying process can be reduced, and its fluidity and stability can be improved. The conveying pipeline should also have good sealing performance to prevent the entry of external impurities and ensure the purity of the material.

Temperature control of materials

The temperature of the material has an important influence on the processing of the Planetary screw extruders. In order to ensure that the material enters the extrusion system at a stable rate, the temperature of the material needs to be precisely controlled.

The temperature control of the material is mainly achieved through the temperature control system. The temperature control system heats and cools the material through the heater and cooler installed on the extruder to ensure that it is processed within the appropriate temperature range. By precisely controlling the temperature of the material, its fluidity and uniformity can be improved, making it easier to be transported by the feeding system.

Mixing and plasticizing of materials

1. Core functions

Mixing and plasticizing of materials is one of the core functions of the Planetary screw extruders. In order to ensure that the material enters the extrusion system at a stable rate, the material needs to be fully mixed and plasticized.

2. Implementation method

The mixing and plasticizing of materials is mainly achieved through the extrusion system.

3. Composition of the extrusion system

The extrusion system includes core components such as the central screw, planetary screw and barrel.

4. Synergy

Through the synergy of these components, the material can be fully mixed and plasticized, and stability and consistency can be maintained during the extrusion process.

5. The role of the central screw and the planetary screw

The rotation of the central screw and the planetary screw can fully mix and plasticize the material, and stability and consistency can be maintained during the extrusion process.

6. The role of the barrel

The barrel controls the temperature of the material through heating and cooling treatment to ensure that it is processed within the appropriate temperature range.

Monitoring and feedback of materials

In order to achieve stable feeding of materials, real-time monitoring and feedback of materials are required. Modern planetary screw extruders usually use advanced monitoring and feedback technology to monitor and adjust materials in real time through sensors and controllers.

English

English 中文简体

中文简体

浙公网安备33090202000520号

浙公网安备33090202000520号