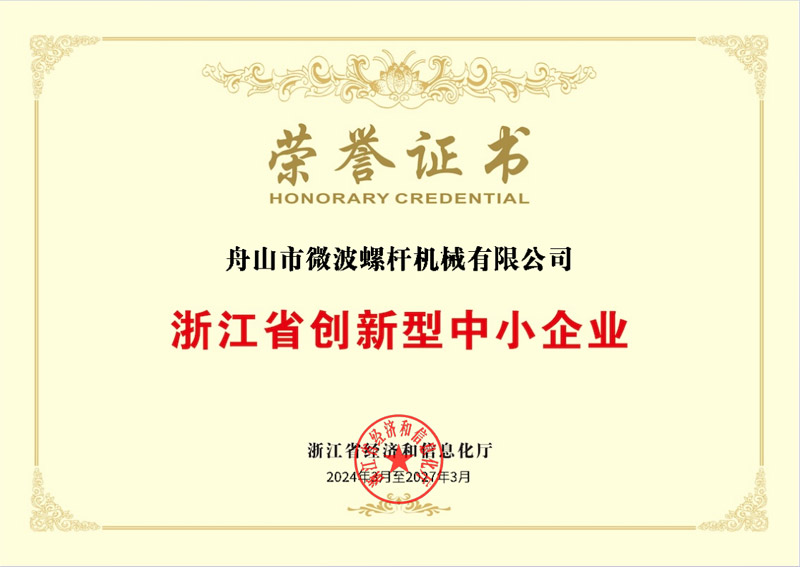

Zhoushan microwave screw machinery Co., LTD is a diversified large-scale professional production base in China. We integrate precision screw barrels and mechanical processing, focusing on the high-end market. Our products are exported to the United States, Germany, Dubai, Vietnam, Thailand and other countries or regions, and have established cooperative relations with many plastic production and construction machinery factories, becoming an important supplier of their mechanical parts. We always adhere to the principle of "reputation first, service first" to provide customers with high-quality products and services.

In our product line, Conical Twin Screw And Barrel is a very important component. It is mainly composed of a drum, a transmission device, a feed port, a discharge port and an exhaust port. During the material processing process, the conical twin screw barrel rotates to place the material inside the drum, and the material is subjected to the centrifugal force and gravity inside the drum to achieve the purpose of mixing, drying, grinding and separation. This design improves the efficiency of material processing, optimizes the distribution of materials on the conveyor, and reduces the possibility of material blockage. Conical Twin Screw And Barrel is widely used as an important industrial equipment in injection molding machines, material mixing, drying, grinding, separation and other process processes. It has a conical appearance and is usually made of metal materials such as nitrided steel 38CrMoAlA.

Our Conical Twin Screw And Barrel products perform well in extrusion machinery such as ordinary plastics, HDPE, SPC, PP, PE, ABS, PVC, raw material granulation, production pipes, special profiles, sheets, wood plastics, etc. The conical structure design of the conical barrel can improve the conveying efficiency of materials on the conveyor. Its special shape can reduce stagnation during material conveying and generate a certain driving force to move the material forward faster and improve the efficiency of the entire conveying line. The design of the conical barrel makes it more adaptable and can be used in a variety of different working environments and usage scenarios.

Whether it is for materials of different particle sizes, or different conveying speeds and conveying distances, our Conical Twin Screw And Barrel can show good performance and stability. The design of the conical barrel also helps to improve the safety and stability of production. Its special structure and rolling mode can reduce the vibration and noise generated during material transportation and reduce the impact on the surrounding environment and equipment. It can better adapt to various abnormal situations on the conveyor line, such as material accumulation, conveyor belt deviation, etc., to ensure the stable operation and production safety of the conveyor line.

In the injection molding machine industry, our Conical Twin Screw And Barrel can manage material mixing more carefully, accurately control the flow and density of materials, and improve the production efficiency and product quality of injection molding machines. We also produce WB-WE series planetary screws, planetary barrels and planetary extruders; SJS series conical twin screws, twin barrels and twin screw plastic extruders; SJ series single screws, single barrels and single screw plastic extruders; pearl cotton screw barrels; and various tube, sheet and profile production lines. These products complement the Conical Twin Screw And Barrel to provide customers with comprehensive plastic processing solutions.

English

English 中文简体

中文简体

浙公网安备33090202000520号

浙公网安备33090202000520号