The Extruder planetary screw barrel adopts advanced design concepts and manufacturing processes, integrating efficient planetary transmission mechanisms, wear-resistant and corrosion-resistant material selection, as well as intelligent temperature control and mixing speed control systems. This system can achieve efficient mixing, dispersion, and grinding of materials in a very short period of time, while maintaining high quality and uniformity of materials, meeting customers' high standard requirements for fine processing.

-

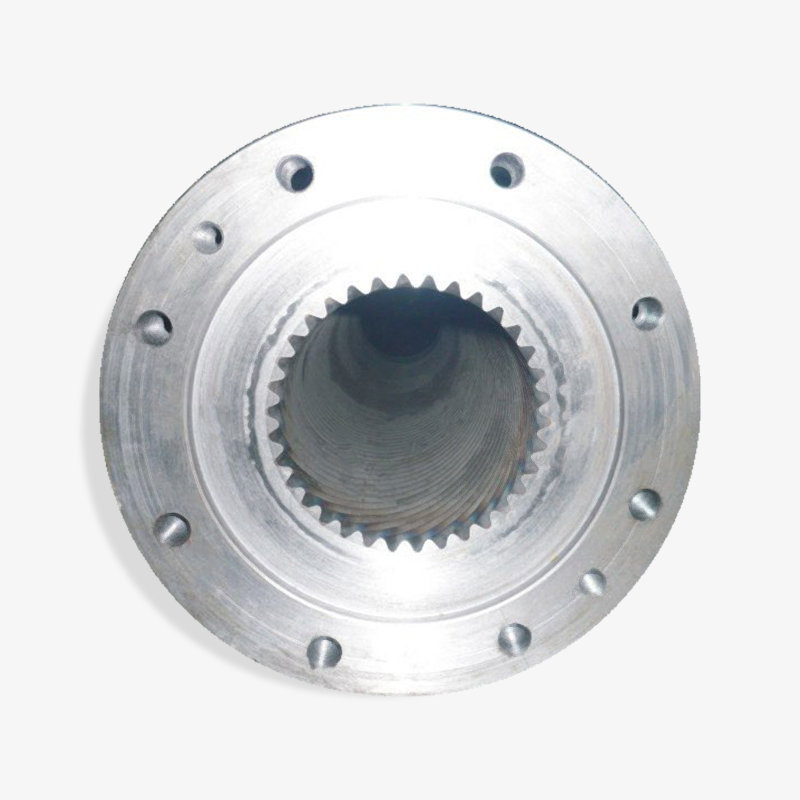

Drawing

Introduction to Parameters/Specifications

Model

Φ 150- Φ 350

Nitriding lip depth

0.5-0.8mm

Nitriding hardness

950-1020HV

Nitriding brittleness

<=Level 1

Surface roughness

Ra0.4um

Screw straightness

0.015mm

Nitriding followed by quenching treatment

Product Usage:

PVC sheet, PVC pipe, PVC granulation, PET sheet

Type:

Pipe extruder, sheet extruder, sheet extruder, process technology, high-frequency quenching, cold and hot spraying hard metal process, advanced nitriding process, bimetallic manufacturing process, and free metal casting alloy.

Main materials:

9Cr18MoV, high-quality 38CrMoAIA, high-quality duplex stainless steel, high-quality powder metallurgy materials.

Product advantages:

The unique design of the Extruder planetary screw barrel ensures that materials are mixed in all directions and without dead corners inside the barrel, greatly improving mixing efficiency and uniformity, and shortening production cycles.

Made of high-quality stainless steel or special alloy materials, it has good wear resistance and corrosion resistance, can resist the erosion of various chemical substances, and extends the service life of equipment.

The Extruder planetary screw barrel is equipped with an intelligent temperature control module, which can automatically adjust the working temperature according to the characteristics of different materials, ensuring the stability and quality of materials during the mixing process, and reducing energy consumption and costs.

The product offers a variety of mixing blade configurations to meet different material characteristics and process requirements, achieving customized production and enhancing product-added value. The structural design is reasonable, easy to disassemble, convenient for daily cleaning and maintenance, reduces downtime, and improves production efficiency. The optimized design of the power system and sealing structure effectively reduces noise and energy consumption, meeting the requirements of modern industry for green environmental protection.

Zhoushan microwave screw machinery Co., LTD is a professional Extruder Planetary Screw Barrel Manufacturers and planetary screw barrel supplier in China, The company has more than 10,000 square meters of production workshop, more than 60 employees. Since its founding in 1990, it has been committed to the production and research of plastic machinery, while introducing foreign screw machinery technology and technology. Main products: WB-WE series planetary screw, planetary barrel and planetary extruder; SJS series conical double screw, double barrel and double screw plastic extruder; SJ series single screw, single barrel and single screw plastic extruder; Pearl-cotton screw barrel; And all kinds of pipe, sheet, shaped production lines. Is a diversified large-scale professional production base in China, set precision screw barrel and machinery machinery processing plant in one, based on high grade and high-end market, mainly exported to the United States, Germany, Dubai, Vietnam, Thailand and many other countries, the cooperation of customers have many plastic production and construction machinery factory customers, Has become an important supplier of their mechanical parts in China. In line with the principle of reputation first, service first, to provide our customers with cheap and beautiful products. Welcome customers to come to negotiate business and create a career.

Commitment To Superior Quality

-

Industry NewsHow to Solve the Seizing Problem of Single Screw Barrels?

In plastic extrusion processing, single screw barrel seizing is a common and serious fault. Seizing not only leads to production line downtime but can also cause further damage to the machine. This article elaborates on this problem from fo...

-

Industry NewsWhy Is the Conical Twin Screw and Barrel Revolutionizing Modern Industrial Processing?

In the fast-paced world of industrial manufacturing, efficiency isn't just a goal—it’s a necessity. From the plastic toys on store shelves to the high-grade pipes used in construction, the machinery behind these products relies on precision...

-

Industry NewsWhy Is Single Screw Barrel Technology the Secret to Smarter Plastic Extrusion?

In the fast-evolving world of manufacturing, efficiency is no longer just a goal—it is a requirement for survival. As industries from construction to food packaging look for ways to streamline their operations, one specific component has em...

Inquiry

Contact

Let’s talk with expertise

phone: +86-13905809051 /

Address: No.3, Hope Avenue, North Industrial Zone, Jintang Town, Dinghai District, Zhoushan City, Zhejiang Province, China

Extruder Planetary Screw Barrel Industry Knowledge

With a production workshop of more than 10,000 square meters and more than 60 employees, Zhoushan microwave screw machinery Co., LTD continuously introduces foreign screw machinery technology and expertise to enhance its product offering. Its main product is the Extruder Planetary Screw Barrel, which is a remarkable innovation in the field of plastic processing. The Extruder Planetary Screw integrates advanced design concepts and manufacturing technologies to ensure efficient planetary transmission mechanisms, wear-resistant and corrosion-resistant materials, and intelligent temperature control and mixing speed regulation systems. The Extruder Planetary Screw is specially designed to quickly mix, disperse and grind materials, maintain high quality and uniformity of materials, and meet the strict requirements of precision processing.

The Extruder Planetary Screw Barrel is particularly suitable for applications such as PVC boards, PVC pipes, PVC granules and PET sheets. Its versatility extends to various extrusion processes, including pipe extrusion, sheet extrusion and film extrusion. The company's expertise in high-frequency quenching, hot and cold hard metal spraying, advanced nitriding processes, bimetallic manufacturing and free metal casting alloys ensures that the Extruder Planetary Screw is made of the highest quality materials, such as 9Cr18MoV, high-quality 38CrMoAlA, high-quality duplex stainless steel and high-quality powder metallurgy materials. These materials contribute to the excellent durability and chemical corrosion resistance of the extruder, extending its service life.

The design of the Extruder Planetary Screw ensures that the materials are fully and seamlessly mixed in the barrel, eliminating dead corners and improving mixing efficiency and uniformity. This design greatly shortens the production cycle and becomes an ideal choice for mass production. The intelligent temperature control module of the Extruder Planetary Screw can automatically adjust the working temperature according to the characteristics of different materials, ensure the stability and quality of the mixing process, and minimize energy consumption and costs.

Zhoushan microwave screw machinery Co., LTD provides a variety of mixing blade configurations for the Extruder Planetary Screw to meet different material characteristics and process requirements. This customization capability enhances the value and adaptability of the product. The company is committed to humanized design, which is also reflected in its easily disassembled extruder structure, which simplifies daily cleaning and maintenance, reduces downtime and improves production efficiency. The optimized power system and sealing structure of the Extruder Planetary Screw also help reduce noise and save energy, meeting the requirements of modern industry for environmental sustainability.

Zhoushan microwave screw machinery Co., LTD is a leading supplier of machinery parts in China, serving many plastic production and construction machinery factories. The company's products include WB-WE series planetary screws, barrels and extruders, SJS series conical twin screws, barrels and extruders, SJ series single screws, barrels and extruders, as well as pearl cotton screw barrels, which are exported to the United States, Germany, Dubai, Vietnam, Thailand and other countries. The company adheres to the principle of reputation first and service first, and is committed to providing customers with high-quality products with high cost performance. The Extruder Planetary Screw Barrel embodies the company's commitment to innovation and excellence in the plastic machinery industry.

English

English 中文简体

中文简体

浙公网安备33090202000520号

浙公网安备33090202000520号